Small Table Top Etching Printing Press

Table Top Etching Press Information

Pressure System:

Pressure System: Printing pressure is applied by lowering the upper pressure drum onto the press bed using the pressure adjusting screws. Micrometer pressure dials are supplied with each press to allow consistent pressure application and repeatability. The upper pressure drum may be raised 1.25" above the bed for relief printing.

Press Bed:

Press Bed: Half-inch blanchard ground aluminum tool plate with a phenolic-resin sheet bonded to the top and bottom surface provides a durable work surface. This surface will withstand all chemicals used in the printing process, very high pressure without embossment problems or loss of printing pressure, and cleans up easily. Uneven printing pressure is eliminated by independently adjustable precision ball bearings supporting the bed.

Frame Unit:

Three-quarter inch by five inch aluminum is paired and machined simultaneously to provide a very accurate and sturdy frame unit. One inch diameter cross bars bolt the frame together. An aluminum frame provides maximum strength, yet reduces the press's weight considerably, making it a more mobile unit.

Pressure and Drive Drums:

Pressure and Drive Drums:Welded drum shaft, support baffles, and heavy wall drum stock are machined to precise specifications as a concentric unit. Maximum drum shaft support is achieved by two self aligning ball bearing support units. This allows the upper pressure drum independent vertical end-to-end travel. All drums are nickel plated. The Pressure Drum is available in standard 4.5" or optional 7 1/2" diameter. The 7 1/2" diameter upper pressure drum option equips your press with a 7 1/2" diameter nickel plated Upper Pressure Drum as opposed to the standard 4 1/2" diameter nickel plated drum. The advantage of this option is a larger diameter Upper Drum will allow the press operator to print with greater pressure with less effort. Although either drum diameter offered will produce excellent results when printing, we recommend the 7 1/2" diameter drum when using heavy pressure.

Internal Bed Stops:

Internal Bed Stops:Bed Stops secure the moving press bed to the press frame. Allows full press bed travel and maxamizes printing area. This feature is a must in today's safety conscious work environment. The internal bed stop design allows full printability of press bed.

Bed Drive System:

Bed Drive System: Effortless hand cranking is made possible by our double reduction chain and sprocket drive system. Polyethylene wear strips attached to each side frame assure minimal bed friction. "See-thru" chain guard covers allow easy inspection of chain lubrication.

Finish:

Finish: All steel press parts are protected by nickel plating, anodizing, high quality paint, or powder coated finish. Custom Colors are available on presses.

Combo Capable:

All Table Top presses are combo capable at no additional cost! Combo capable allows you to purchase either an Etching Press or Litho Press and at a later date order the second Pressure Head, giving you a complete Etching and Litho Combination Press.

Support Bench:

Support Bench: A beautiful and durable 1.75" Michigan hard rock maple table top is attached to a steel table frame. Can be used as a Support Table for Table Top Presses or as a Work Bench for the studio. One lower shelf comes standard; a second shelf may be added, as well as roll around casters for mobility.

Synchronized Pressure System:

Synchronized Pressure System:An optional feature on etching Presses, that allows adjustment of printing pressure from a single side of the printing press. The chain driven pressure screws move in unison, eliminating the need to walk around the etching press to adjust printing pressure. The Synchronized Pressure System ensures even printing pressure without the need of the micrometer dials. It saves valuable print studio space, as it allows a press to be used when placed against a wall. The complete package consists of synchronized pressure system, rotational blanket system and felt blankets. The rotational blanket system raises the felts off of the printing surface, freeing the hands of the printmaker during printing. The Rotational Blanket System feature eliminates the need to handle the blankets as they are neatly kept out of the way while remaining on the etching press ready for use.

Captain's Wheel

Captain's WheelOptional Table Top Captain's Wheel Takes the place of the standard crank handle. 36 " diameter for Table Top Presses.

SIZE SPECIFICATIONS FOR TABLE TOP ETCHING PRESSES |

|||||

|---|---|---|---|---|---|

| Model/Bed Size | 18x36 | 24x36 | 24x48 | 30x48 | 30x60 |

| Overall Height | 19" | 19" | 19" | 19" | 19" |

| Overall Height with Support Bench |

51" | 51" | 51" | 51" | 51" |

| Frame Length | 36" | 36" | 48" | 48" | 60" |

| Frame Width | 19.75" | 25.75" | 25.75" | 31.75" | 31.75" |

| Frame Height | 5" | 5" | 5" | 5" | 5" |

| Bed Length | 36" | 36" | 48" | 48" | 60" |

| Bed Width | 18" | 24" | 24" | 30" | 30" |

| Bed Height | 5.25" | 5.25" | 5.25" | 5.25" | 5.25" |

| Drum Length | 18" | 24" | 24" | 30" | 30" |

| Drum Diameter | 4.75"/7.5" | 4.75"/7.5" | 4.75"/7.5" | 4.75"/7.5" | 4.75"/7.5" |

| Weight with Standard 4.75" drum | 220lb | 270lbs | 295lbs | 335lbs | 370lbs |

| Weight with Large 7.5" drum | 260lbs | 325lbs | 330lbs | 380lbs | 415lbs |

PRICING FOR TABLE TOP ETCHING PRESSES |

||

|---|---|---|

| Press Model (Bed Size) |

Etching Press (standard 4 3/4" Upper Drum) |

Etching Press (optional 7 1/2" Upper Drum) |

| 1836 (18" x 36") |

Item # 0001836 Buy Online |

Item # 00018367 Buy Online |

| 2436 (24" x 36") |

Item # 0002436 Buy Online |

Item # 00024367 Buy Online |

| 2448 (24" x 48") |

Item # 0002448 Buy Online |

Item # 00024487 Buy Online |

3048 |

Item # 0003048 |

Item # 00030487 |

3060 |

Item # 0003060 |

Item # 00030607 |

Etching Blankets

Etching Blankets Etching Press Registration Grid

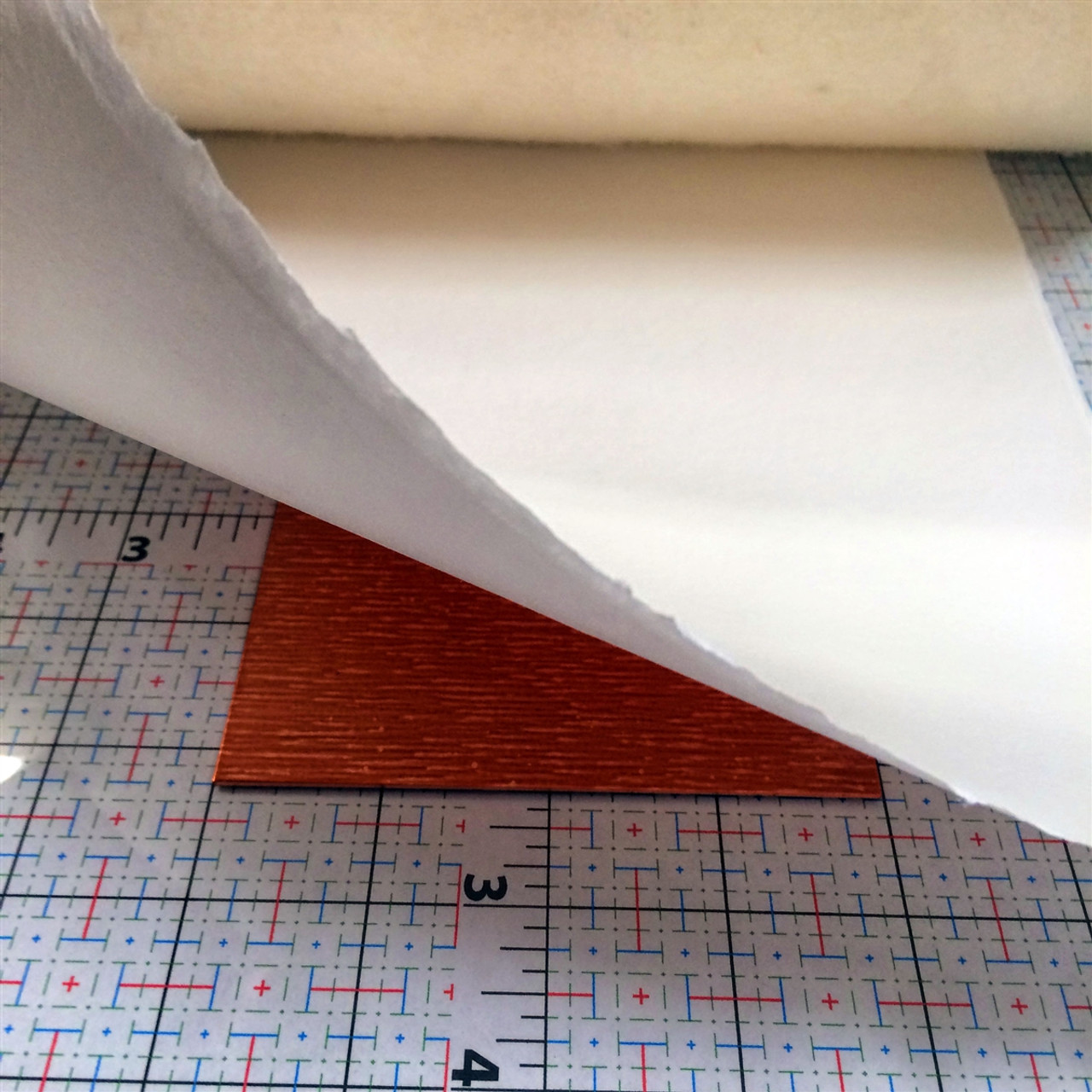

Etching Press Registration Grid Protective Press Bed Cover

Protective Press Bed Cover Support Bench

Support Bench Casters

Casters